The residential properties

in Nayland Rd now stand on a site which began life as a Maltings

(date unknown). The owners were `Freeman - Rodwell`, there was no

connection with the Maltings in Station Hill.

. |

|

This shows the One Bell PH on the

left, in Nayland Rd looking towards the School. After demolition,

it was the car park to the Cheese Factory. When the factory finally

closed the car park was developed with modern residential properties.

The Maltings can clearly be seen on the right, opposite.

We know from local information

that it must have been in business until the 1920`s

|

|

Sometime between the 1920`s

and 1924 the Maltings were converted and taken over by Cornard Mills.

We know from records the Chimney for the boilers was built during 1924,

not only to provide draft for the boilers but to vent the smoke away

from the village.

| It was then the main

dying and fabric finishing works for material that was knitted at

Cornard Mills. Both the Bures and Cornard sites were owned by Melsos.

The local factory here was known as the `Stour Valley Dyeworks" |

|

For something like 30 years Chambers had a contract with the factory

to transport anthracite from the railway station to the factory (and

also the Mill) to fuel the boilers. Transport in those days was by horse

and cart.

In later years the boilers were converted to oil, happily for the residents

this brought and end to the black dense smoke and smuts which belched

from the chimney. The chimney was now redundant, but it continued in

use to vent the boilers. Shortly after the second world war the chimney

was struck by lightening. Large cracks appeared and for safety reasons

the height was lowered and metal bands fitted for support.

During the 1960`s the factory was taken over by Vyella Coates.

Suffolk and Essex Free Press

Thursday 20th February 1947

It would appear the Mill had

a scheduled power failure, possibly by Electricity Board Engineers

working outside.

This allowed them time to bring in an alternative source of

power.

The tractor would have been driving a belt driven alternator.

|

|

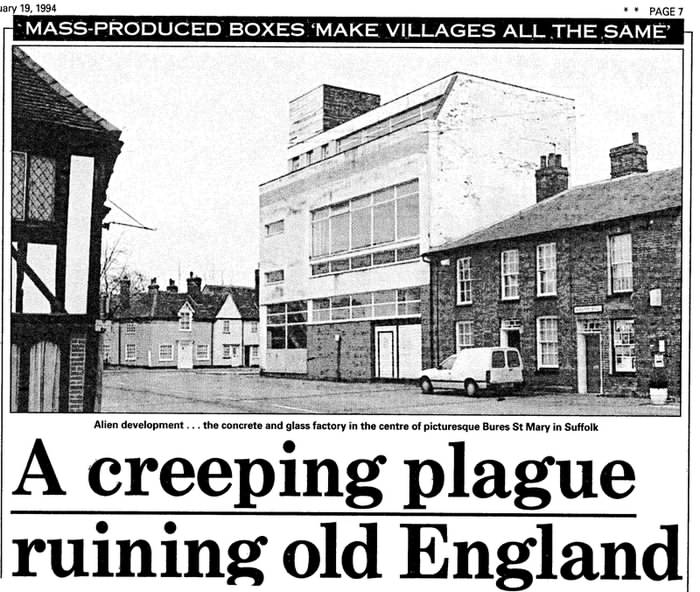

NEW FACTORY

|

|

|

Left:- The new factory rebuilt

after the Fire,

Right:- The new spinning looms

Daily Mail 19.01/1994

|

This was published only

a year before it was demolished

This was published only

a year before it was demolished |

|

|

|

CKM first used a 5 ton Bedford

delivery lorry, but this was later increased to a 7 tons. This

operated on the Bures to Manchester and the Midlands twice weekly

Mon-Wed and Thurs - Fri.

Business was combined with a department of "Bradford Dyers"

Dyers in George Street, Prestwich, Manchester.

Another lorry was used on Wed - Fri to Somerset

Staff would wait for the Somerset lorries return, ready to pick

up the fresh clotted cream it collected from roadside farmshops.

(text by Allan Foote

who drove these vehicles)

|

--------------------------------------------------------------------------------------------------------------

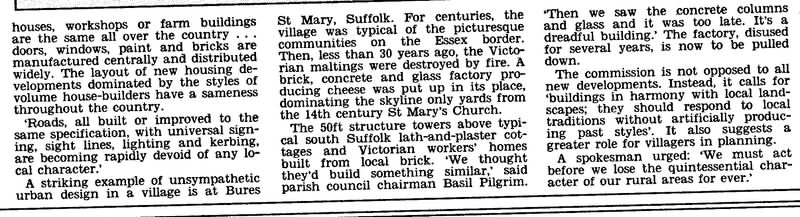

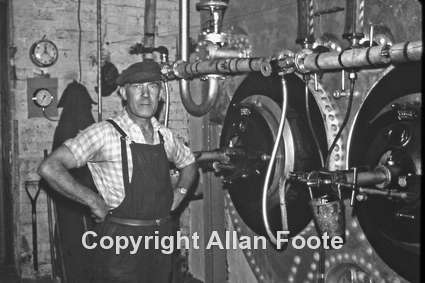

Cornard Knitting Mills, Boilerhouse and staff

Lancashire Oil Filled Boilers

(above)

Note the oval shaped removable disc below the two fire heating

tubes. Wes Cardy and Allan Foote spent a whole summer shutdown,

inside manually descaling the fur from the boiler tubes

They both found that a wandering lamp lead when placed over

the top of a transistor radio acted an an aerial.

Music while you work, to alleviate the boredom.

|

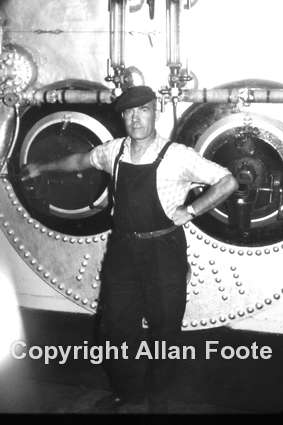

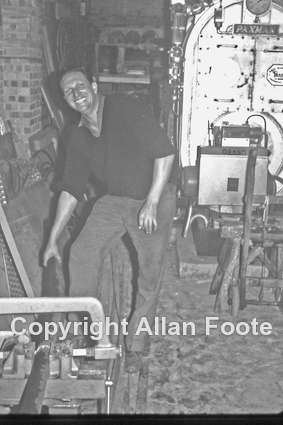

Cyril Smith ( Claypits) and Alf

from Stoke.

Cyril Smith ( Claypits) and Alf

from Stoke. |

Bill, boilerman from Sudbury

|

Cyril Smith alias "The Colonel"

Cyril Smith alias "The Colonel"

|

Bill, boilerman from Sudbury

Bill, boilerman from Sudbury

|

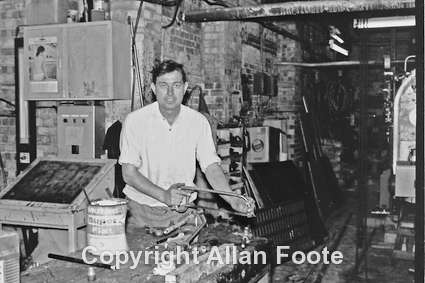

Len Suttonwood. Electrician

Len Suttonwood. Electrician |

|

DYE HOUSE:-

This had beam dying ducts, brushing machines, a cropping machine

and a hydro centrifugal drum dryer

KNITTING SHOP:- had 12 Singer circular

knitting machines making rayon, nylon and cotton fabric for brushed

terry towelling, slipper lining and car stretch seat covers

POWER:-

To the right of the Lancashire boilers was a room that housed

a steam engine driving by a large DC Generator (scrapped 1964)

operated by George Willoughby.

This powered the whole premises

and made it self contained for power. This was before the age

of 240v AC and three phase 440v AC.

The original Hydro was a gigantic DC Motor maintained by George

Willougby from the Nayland Rd.

If a Sudbury chauffeur was going to Col Stn (the car used was

a V10 Jag) to collect Joe Hyman (the Chief, see foot of page)

he would call in and warn all the male staff to get their hats

off. Joe was a strict Jew and he would sack anybody seen wearing

a hat other that a skull cap.

His other policy was to employ two me to do three mens work -

Reasonable Wages !

STAFF

Staff who worked at CKM, but do you know anymore ?

|

Denis Harris

|

Wes Cardy

|

Dave Nichols

|

Ivor Turner

|

David Vango

|

|

Percy and

Vera Street

|

Geof and

Stan Game

|

Len Mcreath

|

Lil Smith

|

Brian Bolton

|

|

Percy Johnson

|

Ted Young

|

Allan Foote

|

Fred Smith

|

|

|

|

Cornard Knitting Mills was also

operating out of property in the High Street, at the same time

as factory had been destroyed by fire.

Orange house, Left side of the entrance to the Croft

This was the administative office dealing with orders, invoices

etc

Courtesy of Heather Andrews, who

was employed there during 1964/65

|

|

During 19 ??, work was subsequently

transferred to the Manchester area and the works closed down

Memories of Bures and

the Dye Works, from Allan Foote, North Wales ( April 2013)

Before Nat. Service,

I used to work as a salesman for a fruit & veg. merchant in Colchester,

and Bures was my destination on a Monday afternoon.

The premises I am referring

to was originally an Oast House on the corner of Nayland Road.

When malting ceased the premises were changed into a dyeworks an was

named Stour Valley Dyeworks. This was purchased by a Mancunian Joe Hyman,

who also owned Melso's in Great Cornard. Joe Sold these out to Vyella

and then he in turn purchased out Vyella and it was named Vyella International

with renouned mills at Pleasley Vale and of course Vyella Fabric. The

Cornard mills was renamed Gainsborough Cornard Ltd and the Bures dyehouse

of S.V.D. was renamed Cornard Knitting Mills Ltd.

Before the fire circular knitting of rayon and nylon fabric was made

on the first floor alongside Nayland Road and was on 3 shift operation,

the dyeworks was operated on a 2 shift operation with the boiler house

operating on 2 shift with a Lancashire oil fired boiler which in turn

generated steam to drive the Direct Current generators to power the

dyehouse machines. Dyeing machines, Raising machines, Cropping machines,

and centrifugal forced spinning machines to extract the water.

After the fire a complete new factory was built on the site by a Sudbury

builder with all local labour.

Staff were bused in from Colchester and Sudbury using our own vehicles

as there was not enough suitable staff in Bures. Staff from the factory/mill

spent quite a lot of their wages in Bures at the time as for one thing

they used the Cafe opps. to 'The Swan' as a canteen at lunchtime. Parcels

were also sent out on a regular daily basis from the Goods dept. at

Bures Railway Station.

After closing down the mill was converted to a cheese factory which

eventually went into liquidation..

No2

I worked for C.K.M. till

redundancy and I am sure there are a lot of past employees who must

have some kind of contribution.

I myself was on the late shift as a CKM personel driver, and I was going

to Colchester and the fire brigade passed us at Bergholt Brewery on

the way to the disastrous fire. Somebody pushed my van out of the enclosed

yard on to the Suffolk Knoll or it would have been destroyed.

New Singer machines were in the pipeline at the time of the fire and

these were set up in Brands up at the Croft, and my mate 'Friar Tuck'

was the warehouseman.

I was employed before redundancy as a long distance driver for C.K.M.

two journeys per week and covered the Midlands but mainly Lancashire

(Manchester) and Yorkshire, delivering rolls of cloth (car seat covers,

slipper fabric) and picking up cotton/nylon yarn from manufacturers

from throughout the north.

There were a lot of people employed at CKM who were characters in their

own right.

N03

The oast house if my memory is correct had two towers/chimineys, on

the buildings alongside Nayland Road I only knew it as a Dye works.

Firstly there was a pair of big double doors on Church Square, in the

centre of the walls, then a double fronted house then the Post Office.

Then behind was a yard area with a yarn store on the left ground floor,

and the knitting shop was on the floor above it. The towers area were

used as storage for finished product, the area to the right was the

dye house which contained the dye vats, spinners, and brushing machines.

The bottom right of the yard was the boiler house, generating room and

workshop, the bottom left area was where the fin. prod. inspection area

was situated.

I nearly got the sack (severe warning) for giving a lift to two young

ladies stranded in Colchester, I was coming out of Colchester by the

Station in the C.K.M. bus about 22.40 and they were thumbing a lift

having missed the last bus. I gave them a lift back to Bures and then

they got somehow a lift to Alpheton from Bures. The next day they had

a request played for me, thanking me for the lift on 'RADIO CAROLINE'

which was played out in the knitting shop on full volume to drown the

noise of the knitting machines, for all to hear including my manager

who was not too pleased.

Note:- CKM refers to

Cornard Knitting Mills

Memories of Bures and

the Dye Works, from Dougie Dingwall, Norwich ( Dec2015)

My Godfather Fred Smith was another

member of the CKM staff. He is shown here along with his wife at the

CKM Christmas.

I believe he was a foreman there. They lived on Nayland Road opposite

Bures House, and next to the One Bell Inn, where I lived. Being four

at the time I have some vague memories of the factory fire in 1964.

We were evacuated from the pub and stayed the night with Gert &

Fred. My father Jim, elected to stay at the pub to ensure its safety

and supply the firemen with refreshments. As a large part of the pub

was of timber construction, the firemen sprayed water on it all night,

to prevent any stray burning debris setting fire to it. I remember

a few days later Fred took me to look around the burnt out factory,

my only recollection of that is the smell of smoke and the amount

of water laying around.

Fred was one of the lucky ones, when the mill eventually closed down

he was transferred to their Cornard site.

CHEESE

FACTORY

After the Knitting Mills

closed the site was sold to Swifts an American based company as a Cheese

Factory, processing waste cheese from retail outlets. Lorries from such

stores as Tesco`s, Dairy Crest etc and delivered the cheese which was

then reconstituted and resold.

A large quantity of cheese was packaged in large tins for the army as

well as cheese slices.

It employed a large number of villagers some estimating as many as about

60 employees.

Some names which were remembered:-

| Ethel Staples |

Freda Garrad |

Joyce Norris |

Bernie Clampin |

Doreen Warden |

Mable Hume |

| Pearl Cousins |

Janet Dolland |

Betty Wilkinson |

Joan Baldwyn |

Eileen Joyce |

Dick Kemp |

| Maureen Row |

Patricia Thomson |

Debbie Rickard |

|

|

|

Can you recall anymore names?

During lunchtime the "Three

Ways Cafe" over in Bridge Street was a popular venue for refreshments

It is well remembered, because of it`s very characteristic pungent smell

of boiled-up cheese, which drifted across the village!

|

|

| Front

Row |

|

|

Peter

Powell |

Peter

Felton |

| Back Row |

|

|

|

Howard Parkinson |

Can anyone put any further names to these eight Factory Workers

? |

Cheese Factory during the 1970`s |

Staff car park which stood on the site of the "One Bell PH"

1973 |

Swifts loading bay taken from

staff car park during 1973

|

Aerial View of Factory. The chimney and Bures House the the bottom

centre of the photograph can clearly be seen. |

|

|

|

1992 Cheese Factory with Steam

Hauled excursion on Railway Line.

Bures House can be seen to the left of the factory. |

Memories of the

Cheese Factory, Alan Beales

I recall visiting

the village during 1974 with my wife, to view at a property along

Cuckoo Hill which I was interested in purchasing.

Standing in the garden, my wife and myself couldnt help but notice,

the odd smell in the air

"Whatever is that" we remarked

About an hour later we called into the Post Office and asked the

lady (we now know as Angela Harrod) behind the counter "Whats

the smell" ?

I cannot recall getting a definitive

answer but she replied "What Smell"

After we moved into

our house, on many occassions when the wind was in the right direction

we had to close the windows to keep the odour of boiled cheese

outside and yes, we did get used to it after a few months.

After its closure it was left unoccupied for several years eventually

becoming an eyesore in the heart of the village. Despite many

plans for the building nothing ever materialised.

Finally in Feb 1995, the chimney was demolished and work started

on the construction of a new housing development.

|

|

|

|

|

Factory Site now

re-built as residential properties.

|

|

Bures

House - Built 1850 by James Dalton who owned the Maltings

next door. He lived in these premises with the servants and staff

occupying the basement.

Hitchcocks (previously family of the Mill) occupied these premises

from 1875.

W.Church (founder of Church`s seeds) moved in shortly after 1913.

Photo taken 2006 |

Fire destroyed the house on 6th January

1982. More than 30 fireman fought for 2 hours to control the blaze. The

fire started in the roof and was so extensive, water was pumped by a system

of relay pumps from the River Stour. The damage to the 150 year old house

was estimated to be over £50,000.

Author:- I can recall personally returning from work in Colchester

at approximately 5.30pm and when I reached the top of Wormingford Hill

I could see the fire in the distance. It was dark at that time of the

year but the glow from the fire seemed to blanket the entire centre of

the village. A sight I can still recall to this day.

It was subsequently internally gutted and

re-built into flats with the adjacent land sold as an additional building

plot.

`Garden House` was constructed approx. 1982 and now stands on the site

of the garden and tennis courts that once belonged to Bures House.

NOTES

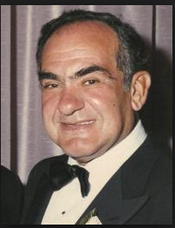

JOE HYMAN owner of CKM

|

In the 1960s, when industrial and

managerial renaissance seemed to be reinvigorating the British economy,

Joe Hyman, was among the most vital and successful of the new men.

.

Hyman had remarkable qualities

- imagination, boldness, the ability to grasp the implications of

new technology, strong marketing sense, and a mastery of finance

that amounted to near-genius. As for the unfortunate choice of textiles,

that was an accident of birth. His grandfather and father were both

textile merchants, and Hyman left Manchester grammar school at 16

to get a start in the industry.

Working for others, even his father,

was not Hyman's style. After an early failure, he bought a small

Suffolk knitting firm in 1957, renamed it Gainsborough Fabrics at

Gt Cornard, and immediately demonstrated how new fabrics and production

methods could raise demand and bring down costs.

|

He also understood the principles of growing

by acquisition. The next buy was the Cornard Knitting Mill (Bures), followed

in 1961 by William Hollins. Unlike most of the many (too many) textile

firms of the day, Hollins possessed a national consumer brand: Viyella,

best-known for warm pyjamas.

The prime combatants, however, were

two industrial giants, ICI and Courtaulds, once partners in nylon. The

partnership degenerated into open hostility, which culminated in a celebrated

takeover battle when ICI was defeated.

So we were left with ICI and Joe Hyman

as the main textile giants

Having built his original rise on brushed

nylon, which accounted for massive shirt sales through Marks & Spencer,

Hyman was quick to see the superior potential of polyester-cotton mixtures.

ICI had pioneered the synthetic, but showed far less imagination than

its protégé when it came to commercial exploitation.

The two were ill-suited partners.

ICI was managed by career chemical engineers with little customer focus;

Viyella International, as it became, was led by a multi-talented, multi-millionaire

entrepreneur with an instinctive feel for markets.

The original cuddly, warm Viyella

brand, for example, was transformed into a fabric range that had broad,

modern appeal. Using his skills as a financial engineer, Hyman then added

other companies and brands, notably Van Heusen, as he vied with Kearton

to transform textiles into a world-beating industry.

But the effort was doomed, as was the ICI

relationship. At a celebrated, late-night board meeting in December 1969,

Hyman's underlings turned on the demanding master who had both dominated

and inspired them. Whatever part ICI played -or did not play - in the

ousting, his career as an industrial shaper and maker was over.

Joe Hyman b1921 d1999

Updated 18/04/2013

Updated 22/06/2014 new photos

Submission by Allan Foote

updated 14/03/2015

Boileroom photographs courtesy of Allan Foote

updated 15/03/2015

Complete web page re-written

updated 03/12/2015

Notes by dougie Dingwall

Updated 12/09/20

Daily Mail by Susan Ashdown

|